Moisture Condition Value (MCV) Testing Myth-Busted!

Posted on 11th April 2024

We come across many earthworks specifications calling for, amongst other things, MCV testing as part of the classification regime to establish whether the material conforms. Stop! To just carry out an MCV test on it’s own at the classification stage is pointless.

MCV testing is designed to replace actual water content measurements of cohesive fill material during the laying and compacting process. Water content tests can take 24 hours before the result is known (as the sample has to be dried in an oven overnight) so if a fill material has failed the boundaries of acceptable water content it could be a day before this is known and the material could be buried under several other layers of fill! To overcome this time-issue then good practice using an MCV could take the form of:-

Before Laying and Compacting

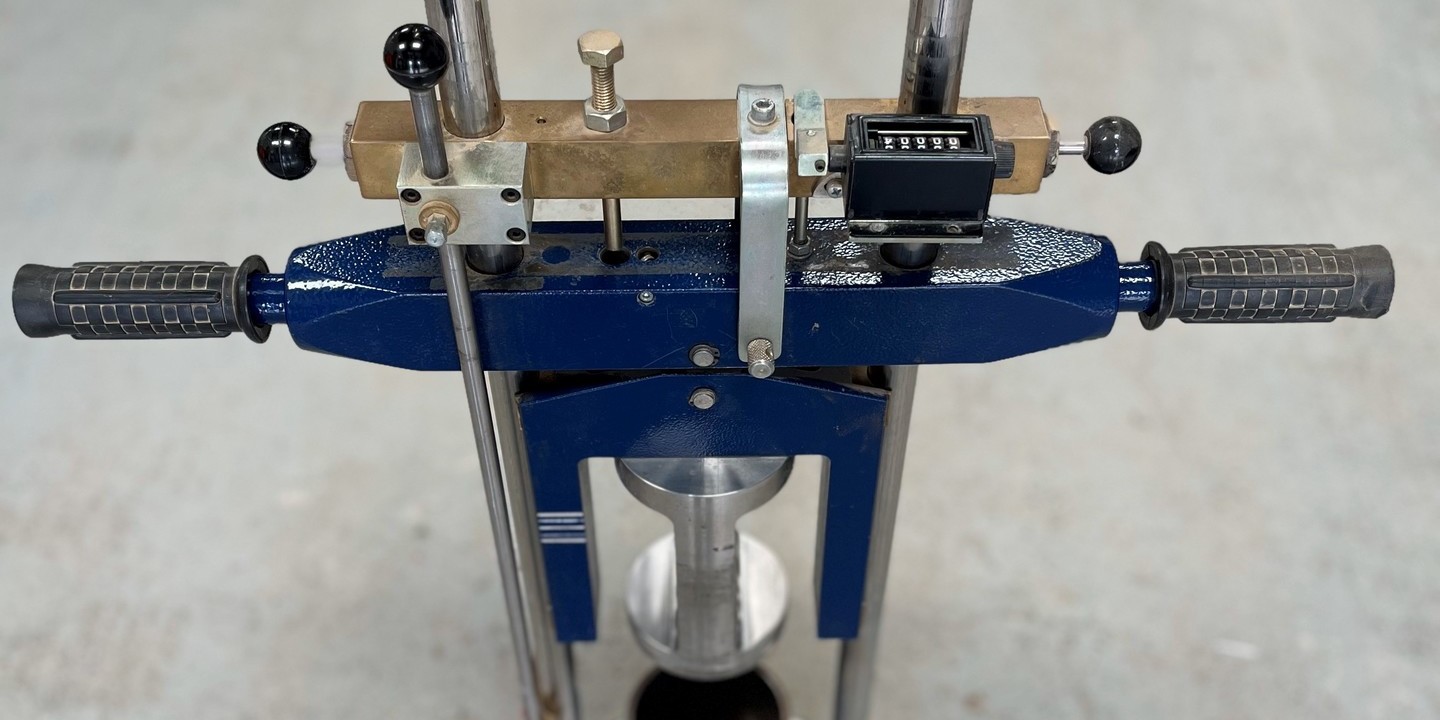

1. Establish the maximum dry density and optimum water content of the fill material using a dropping hammer compaction test.

2. Conduct an MCV test at several water contents above and below the optimum water content to establish a relationship between water content and MCV.

3. Establish what minimum and maximum MCV values equate to a water content compliant with the specification.

Laying and Compacting

1. Conduct regular MCV tests on-site as the fill material is ready for compacting and get an instant result of compliance (or not)!

We are always ready to help you get the most out of your testing. Please get in touch if you’d like to know more.

Contact Hixtra Today

Tagged as: MCV, Moisture Condition Value

Share this post: